High Rise Building Demolition - Bottom Up Method

High Rise Building Demolition -

Bottom Up Method

Kajima Corporation Buildings –

Demolition Methodology

“There

are so many quiet revolutions going on in tall buildings. Top-down construction

is one such revolution, and here is another—bottom-up demolition.”

Location

Tokyo

Completion Date

Tower

1: 1968

Tower

2: 1972Demolition Date

2008Height

Tower

1: 76 m (249 ft)

Tower

2: 65m (213 ft)Stories

Tower

1: 20

Tower

2: 17Primary Use

Office

The

demolition of older tall buildings is increasingly becoming an issue with the

impact on the environment and re-use of materials. The new Kajima method offers

a solution which addresses and improves upon typical demolition methods. This

method will improve the sustainability of a building through its lifespan and

final deconstruction. Aside from improving sustainability, this method also

decreases the impact of demolition on its surroundings.

|

|

|

| ||

Figure 1. Demolition sequence: March 08

|

Figure 2. Demolition sequence: May 08

|

Figure 3. Demolition sequence: July 08

|

A

high-rise construction boom in Japan during the 1960s and 1970s has resulted in

a large amount of aging towers. Building owners have an interest in demolishing

the old structures to replace them with more modern, safe, and work-friendly

buildings, but there are several issues to address in this process.

The

Kajima “Cut and Take Down Method” was developed to satisfy both safety and

environmental concerns. In April 2007, Kajima started to develop this new

demolition method to demolish its aging office headquarters buildings, which

were 76 meters tall and 65 meters tall.

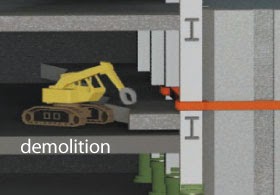

Buildings

are usually demolished by placing heavy equipment and workers on the top floor

and then lowering the waste material down to ground level. The “Cut and Take

Down Method” alternatively allows the workers to start at the base and work

their way up. By starting at the bottom, gutting one floor, and then lowering

the entire building on jacks one floor at a time, all work can be performed

safely at ground level.

On

the 85 by 60 meter site, the two towers were situated quite close to another

office building and a residential building, emphasizing the need for a clean,

quiet demolition process. To accomplish this, temporary columns are used around

the structural column grid, the existing columns are replaced, and then

hydraulic jacks are placed where the existing columns were and the building can

be lowered to the next floor plate where the process is repeated.

The

hydraulic jacks each had a capacity of 1,200 tons, and supported the structure

through each cycle of lowering. A cycle would lower the whole building by 675

mm, which meant that five cycles were required for each floor (total of 3.375

meters). The total time to demolish a whole floor was six days: 2.5 days for

lowering and the remaining time to demolish the rest of the structure.

.

|

|

|

| |

Figure 3. Demolition process step 1: Cut the column. Cut length of 70 centimeters for a column and take off

| ||

|

|

| |

Figure 4. Demolition process step 2: Extend the jack stroke. Extend length of 70 centimeters for jack stroke

| ||

|

|

| |

Figure 5. Demolition process step 3: Take down all jacks. After doing step 1 & 2 for all columns, all jacks were taken down

| ||

|

|

| |

Figure 6. Demolition process step 4: Take out beams and floor slab of the floor above

| ||

A

“core wall and load transferring frame” system are utilized to temporarily

reinforce the structure to prevent any lateral movements due to wind or

earthquake forces. The core wall was 400–900 mm thick reinforced concrete and

was placed in the center of the floor plates up to the third level to take any

lateral forces of the superstructure. To ensure the transfer of lateral loads,

the load transferring frame was installed in steel and connected to the

existing structure. It was then tied into the core wall with a track-like

system, which would lock in place in the event of an earthquake.

The

new method allows the dismantled building to keep the same level of seismic and

wind resistance capability as its original design. It also reduces the amount

of noise as compared with typical top-down approaches, because all the work is

being completed at the ground level. Safety of workers is increased as well,

due to the location of all the work being at ground level as opposed to the

building top.

Figure

7. Removing columns after cutting

In

considering the reduction of site waste being sent to landfills, this new

method allows for a more efficient system of recycling and reusing. The

orderliness of the process means that the materials from each floor may be

sorted effectively so the maximum amount of material is sent to its rightful

place instead of batches of material getting sent to the landfill without

adequate sorting. The Kajima Towers were able to be sorted into 30 types of

materials for recycling, as opposed to a typical 20 at other demolition sites.

The recycling rate was over 90% for the interiors of the buildings, surpassing

the average 55%.

Although

this method was developed for a building with steel frame structure up to 20

stories high, it can be applied to larger-scale buildings as well. Furthermore,

this process is especially useful in densely built areas where typical

demolition may impact neighboring buildings. The demolition of the two Kajima

Towers was completed in nine months for the 20- and 17-story buildings. Though

the costs of this method may be 5–10% higher than traditional methods, the

total time of demolition can be decreased by 15%, increasing the turnover rate

of the site.

Figure

9. Core wall demolition

No comments

Post a Comment